1. Eliminate all the waste in the fulfillment stream so that only value remains

2. Make customer consumption visible to all members of the fulfilment stream

3. Reduce lead time

4. Create level flow

5. Use pull systems

6. Increase velocity and reduce variation

7. Collaborate and use process discipline

8. Focus on total cost of fulfillment

|

| Add caption |

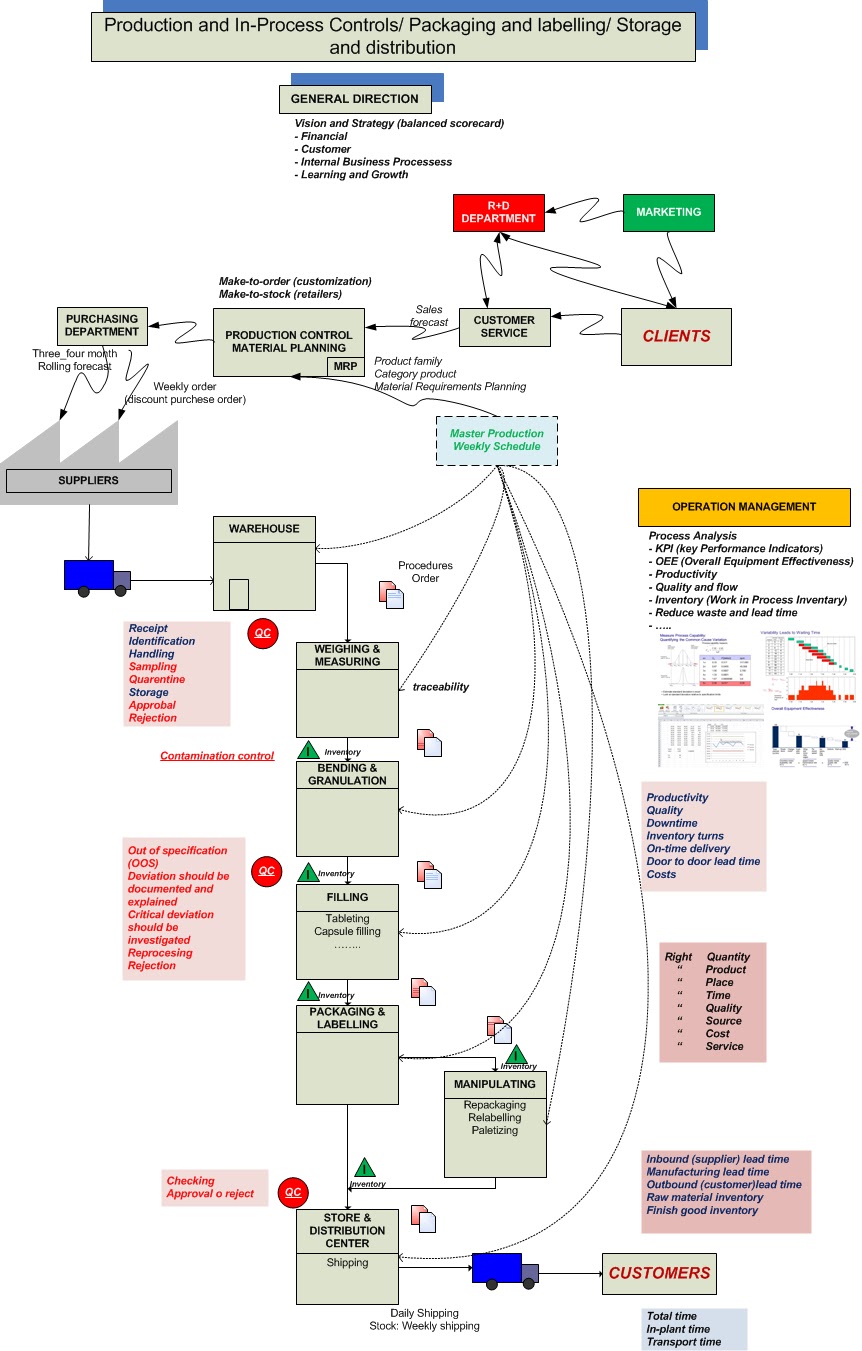

Total lead time is the sum of all processing time, transit time, and time spent as inventory.

Inbound (supplier) lead time: The amount of time from the

point of ordering materials (APIs, raw materials, packaging,..) from a

supplier to the point the material is received and available for use.

Manufacturing lead time: The amount of time it takes to

send an order to production planning and for the goods to be

manufactured and made available for shipping.

Outbound (customer) lead time: The amount of time it takes for a clients order to be received, processed, and shipped to the customer.

Raw material inventory: The amount of inventory that sits as raw material in front of the manufacturing process, measured in average days on hand.

Finished-goods inventory: The amount of inventory that sits in finished goods.

Perfect-order execution

1. Right quantity: How often the rigth quantity of material is sent to the next step in the fulfillment stream.

2. Right product: How often the right product is sent to the next step.

3. Right place: How often the material is sent to the right place in in the stream.

4. Right time: How often materaisl ase sent on time to the next step.

5. Right quality: How often material is sent with perfect quality to the next step. This includes quality of product and accuracy of information.

6. Right source: How often the materials are sourced from the right supplier.

7. Right price: How often the organization pays the planned price (or cost) for materials.

8. Right service: How often the downstream customer receives expected service.

Productivity= Units Output produced/ Input used

Labor productivity= p.e. 10units per labor hour

Multifactor productivity

Productivity=Output/(Capital€+Labor€+Materials€+Service€+Energy€)

Waste (overproduction, transportation, rework, over-processing, motion, inventory)

Information source: Building a Lean Fulfillment Stream by Robert Martichenko and Kevin von Grade- Lean Interprice Institute